DRO

Rotary kiln sealing system

DRO

Rotary kiln sealing system

DRO Single seal

| Item | Designation |

| 1 | Mounting flange (kiln shell) |

| 2 | Seal disc (rotating) |

| 3 | Bronze seal face |

| 4 | Packing ring (static) |

| 5 | Housing |

| 6 | Expansion joint |

| 7 | Spring system |

| 8 | Thermal sensor fitting |

| 9 | Flush fitting |

DRO

Rotary kiln sealing system

Features

- Packing rings (self-adjusting) with permanent spring-action for optimal, continuous contact with the seal disc, optical wear indicator

- Can be pressurized with buffer gas

- Optional dust extraction at the expansion joint

- Optional flush fitting to remove dust deposits at the seal disc

- Double-acting seal rings for use with process-compatible barrier gas or to drain toxic or aggressive gas

- Cutting-edge materials, supports broad range of applications

Advantages

- Reduced pollution emissions

- Clean residue combustion

- No partial temperature reduction below the residue combustion threshold due to air infiltration (no dioxin formation)

- Safe operation

- Significant reduction in primary energy consumption

- Long service life, low wear

- Predictable downtime (e.g. annual inspection)

- Available as retrofit on existing systems

Materials

Metal parts: Steel S235JR (St 37-2 / 1.0037),

CrNiMo steel (1.4571)

Other materials on request.

CrNiMo steel (1.4571)

Other materials on request.

Recommended applications

- Process industry

- Petrochemical industry

- Chemical industry

- Pharmaceutical industry

- Toxic, hazardous, chemical media

- Residue and waste incineration

- Cement production

- Calcination

- Reduction

Functional description

The sealing system consists of a mounting flange welded on to the kiln shell. The two connected halves of the split case engage at the seal disk which is screw mounted to the flange. Depending on requirements, two or four packing rings are provided and a thrust ring presses them against the seal disk. A spring mechanism generates the contact force for the packing rings.

A specially designed expansion joint compensates for axial (thermal) expansion and change in the position of the kiln shell. A torque damper prevents rotation of the seal carrier assembly.

With the exception of the seal disc, the entire sealing system is free moving and runs on roller supports in the damper. The seal is able to follow any movement by the oven with the sealing function remaining intact.

The seal disc compensates for radial deflection of the rotary kiln (caused by ovality, etc.) by submerging to a greater or lesser extent into the seal housing.

A specially designed expansion joint compensates for axial (thermal) expansion and change in the position of the kiln shell. A torque damper prevents rotation of the seal carrier assembly.

With the exception of the seal disc, the entire sealing system is free moving and runs on roller supports in the damper. The seal is able to follow any movement by the oven with the sealing function remaining intact.

The seal disc compensates for radial deflection of the rotary kiln (caused by ovality, etc.) by submerging to a greater or lesser extent into the seal housing.

Product variants

DRO Double seal

| Item | Designation |

| 1 | Mounting flange (kiln shell) |

| 2 | Seal disc (rotating) |

| 3 | Bronze seal face |

| 4 | Packing ring (static) |

| 5 | Housing |

| 6 | Expansion joint |

| 7 | Flush fitting |

| 8 | Spring system |

Similar products

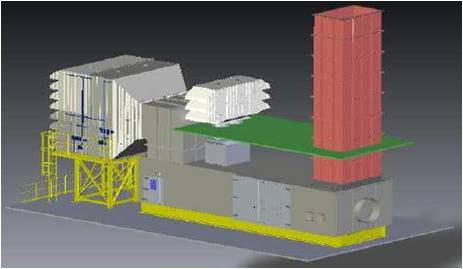

Turbine cabins

Turbine cabins, air filtrate sealing system and filter houses are made for containing filtered air, to protect the turbine mechanic integrity and to avoid gas leaks to the media.

The turbine cabines consist of panels built in different layers to seal and isolate noise and heat and seal the filtered air. The assembly between doors and panels are by means of special shaped gaskets sealed air tight. Further parts are included as custom made ducts, textile expansion joints, locks, dampers, actuators, sealing monitor devices.

The turbine cabines consist of panels built in different layers to seal and isolate noise and heat and seal the filtered air. The assembly between doors and panels are by means of special shaped gaskets sealed air tight. Further parts are included as custom made ducts, textile expansion joints, locks, dampers, actuators, sealing monitor devices.